In modern kitchen design, aesthetics and functionality are no longer separate goals — they are one and the same. Clients demand clean, seamless, and intelligent lighting that elevates their living experience without visible complexity.

That’s where Invisible Wire LED Lighting enters the scene — a next-generation solution that eliminates visible cabling while delivering high-performance, energy-efficient illumination.

For architects, kitchen manufacturers, and lighting integrators, this technology is redefining how LED systems are specified, installed, and perceived. It’s not just a design trend — it’s a technological leap in LED power delivery and visual integration.

Table of Contents

What Is Invisible Wire LED Lighting?

Invisible wire LED lighting uses transparent conductive materials — often ultra-thin copper or silver-based micro-filaments laminated between insulating layers — to deliver electrical power to LED modules without exposed wiring.

This creates a “floating light” effect that gives the illusion of wireless power transmission while maintaining full electrical integrity.

🔧 Technical Highlights:

- Transparent power transmission: Conductive micro-filament or film replaces traditional copper wire

- Seamless integration: No visible connectors or cables

- Low voltage (12V/24V DC): Safe for furniture, cabinetry, and interior applications

- High compatibility: Works with COB or SMD LED strips

- Customizable configuration: Flexible for OEM and architectural design needs

This innovation allows manufacturers to design floating shelves, frameless cabinets, and ultra-minimal installations where light becomes part of the structure itself.

🧠 Why It Matters for the B2B LED Market

Invisible wire LED lighting represents a significant step in lighting product differentiation, system integration, and market positioning.

A New Value Proposition for OEM and ODM Partners

For LED manufacturers and kitchen system brands, invisible wiring technology opens opportunities for product innovation and exclusivity.

Imagine offering clients:

- Floating illuminated shelves that require no visible cables

- Seamless LED panels for luxury kitchen cabinetry

- Plug-free lighting modules embedded directly into wood, glass, or acrylic

These unique applications enable brands to differentiate in a competitive market where most products still rely on visible connectors or aluminum profiles.

Enhanced Aesthetics for High-End Projects

Architectural and interior designers increasingly demand unbroken visual lines. Traditional LED strips with junctions, solder joints, or visible wiring disrupt the design narrative.

Invisible wire LED solutions provide a continuous, dot-free light surface ideal for premium kitchens, showrooms, and smart home environments.

For manufacturers, this aesthetic advantage translates to higher market value, premium positioning, and designer collaboration opportunities.

Simplified Installation for Integrators

For electrical contractors and integrators, invisible wire systems reduce installation complexity:

- Pre-laminated conductive surfaces mean fewer mechanical connections

- No need for bulky aluminum channels or visible terminals

- Lightweight design simplifies hidden mounting in cabinetry or walls

Faster installation = lower labor costs and fewer on-site errors — a significant benefit in commercial kitchen, retail, and hospitality projects.

Smart Compatibility with Future Systems

Invisible wire LED platforms are compatible with:

- Tunable white (CCT adjustable) systems

- DALI / DMX / smart controls

- Low-voltage power distribution grids used in modular architecture

This makes them ideal for integration with smart kitchens, IoT-connected homes, and energy management systems — a strong selling point for forward-thinking developers.

🧩 Applications Across the Value Chain

🔹 Kitchen and Furniture Manufacturers

Integrate invisible wire LED systems directly into kitchen modules, countertops, or glass shelving to offer ready-to-install illuminated furniture.

- Plug-and-play assembly for production lines

- Compatible with wood, stone, and glass materials

- Adds premium visual value with minimal design intrusion

🔹 Architectural Lighting Designers

Use invisible LED wiring for:

- Floating shelves and decorative displays

- Under-cabinet and cove illumination

- Invisible linear accents in minimalist interiors

This provides design flexibility without compromising aesthetics or safety.

🔹 OEM LED Strip Manufacturers

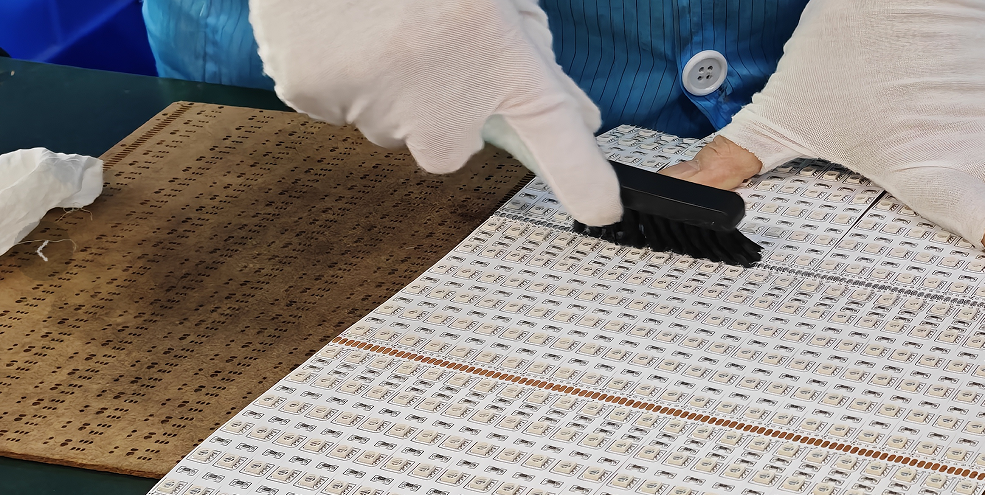

Collaborate with invisible wire technology suppliers to develop customized PCB or FPC integrations, creating a new generation of LED strips that appear “wireless.”

🔹 System Integrators and Contractors

Offer smart lighting packages that include invisible wire solutions for high-end residential, hospitality, or retail clients seeking clean, modern aesthetics.

🏗️ The Technology Behind Invisible Power Transmission

The magic lies in transparent conductive films (TCF) — advanced materials that replace visible copper wires with invisible circuits.

Material Examples:

- ITO (Indium Tin Oxide) film: Transparent but conductive

- Nano-silver film: Highly conductive, flexible, and durable

- Copper microfilament mesh: Embedded between insulation layers

These materials are applied to glass, acrylic, or polymer substrates, forming a virtually invisible electrical path that powers LED modules.

When paired with COB LED strips, the result is an uninterrupted line of light that appears to float freely, ideal for luxury kitchens, architectural facades, or modern retail displays.

🌍 Market Perspective: Where Demand Is Growing

Invisible wire LED lighting is gaining traction in several global markets:

|

Region |

Application Focus |

Market Trend |

|

Europe |

Luxury kitchen and bespoke furniture lighting |

Integration into smart home design |

|

North America |

Premium residential and retail display lighting |

Growing demand for aesthetic minimalism |

|

Middle East |

Hospitality and high-end retail |

Architectural lighting and smart interiors |

|

Asia-Pacific |

OEM LED manufacturing |

Integration into modular kitchen production lines |

⚡ Installation and Integration Considerations

When integrating invisible wire LED systems, B2B users should focus on:

- Power management: Use regulated low-voltage drivers (12V/24V DC).

- Connector design: Transparent connectors ensure seamless transitions.

- Thermal management: COB LEDs generate heat — proper dissipation is critical.

- Material compatibility: Match conductive film type with surface material.

- Safety and certification: Ensure compliance with CE, UL, and RoHS standards.

These systems are typically modular and custom-designed per project, making them ideal for OEM or project-based business models.

🔋 Sustainability and Efficiency

Invisible wire LED systems consume less power than traditional under-cabinet lighting. The combination of COB LEDs + transparent wiring minimizes energy waste while maintaining 90+ CRI quality.

The lack of visible components also reduces material use, aligning with sustainable design principles.

For B2B clients, this means stronger ESG alignment and market appeal among eco-conscious developers and specifiers.

🏁 Conclusion

Invisible wire LED lighting isn’t just another product — it’s a design and engineering evolution that bridges technology, aesthetics, and sustainability.

As we move deeper into 2025, invisible wire LED systems will define the next generation of premium kitchen and interior lighting solutions — lighting you can’t see, but can’t live without.

As a bespoke lighting solution provider, Yiholight specializes in high-quality LED strips, flex neon strip, LED downlight, LED track light. Our products are engineered for durability, brightness, and ease of installation—trusted by B2B customers across the globe.

Contact us today to explore the best LED lighting for your business!

© [Yiholight] and [www.yiholight.com]. Unauthorized use or duplication of this material is strictly prohibited without express written permission from the site’s author or owner. Excerpts and links may be used, provided full, clear credit is given to [Yiholight] and [www.yiholight.com], with appropriate, specific direction to the original content.