If you have ever sourced LED strip lighting, you’ve probably noticed one confusing reality:

Products that look similar on the surface can have prices that differ by 30%, 50%, or even 100%.

For many buyers, especially those sourcing from overseas suppliers, this price gap raises important questions:

- Are expensive LED strips really better?

- Why do some quotes seem unrealistically low?

- What hidden costs exist behind a cheap price?

In this article, we explain why LED strip prices vary so much, breaking down the real cost drivers behind pricing — and what buyers are actually paying for.

Table of Contents

LED Chip Quality Is the Biggest Price Driver

The LED chip is the most important component in any LED strip — and also one of the biggest cost variables.

High-quality LED chips offer:

- Stable lumen output

- Consistent color temperature

- Low failure rate

- Long lifespan

Low-cost LED chips often result in:

- Rapid brightness decay

- Color shift over time

- Higher dead LED rate

- Shorter working life

Even when two LED strips claim the same wattage and brightness, the real performance over time can be completely different.

💡 Price difference starts at the component level — long before assembly.

Color Quality & Binning Control Cost Money

Many low-priced LED strips advertise:

- “CRI 90”

- “Warm white 3000K”

- “High consistency”

But in reality, without strict binning control:

- One batch may look warm

- Another may look greenish or pink

- Installed strips may not match visually

High-quality manufacturers invest in:

- Tight SDCM control (≤3)

- Batch consistency management

- Color testing during production

This level of control adds cost, but is essential for architectural and commercial projects.

PCB Design & Copper Thickness

PCB quality is often invisible to buyers — but it directly affects performance.

Higher-cost LED strips use:

- Thicker copper layers

- Better thermal conductivity

- Stable flexible substrates

Cheaper LED strips often use:

- Thin copper

- Narrow traces

- Minimal thermal margin

Result:

- More voltage drop

- Higher heat accumulation

- Shortened lifespan

📌 Better PCB = higher material cost + better reliability.

Heat Management & Power Design

Some LED strips are designed to look bright on paper, but are actually overdriven.

Low-price strategy:

- Push LEDs beyond optimal current

- Advertise high lumen output

- Ignore long-term degradation

Professional design approach:

- Conservative power design

- Proper current distribution

- Real operating temperature testing

This difference alone can explain a significant price gap.

🔥 Heat kills LEDs — managing it properly costs money.

Real vs Claimed Lumen Output

Many LED strips list impressive lumen numbers — but not all values are measured honestly.

Low-price products may:

- Use theoretical lumen calculations

- Test without considering heat

- Ignore lumen depreciation

High-quality products:

- Measure real output

- Provide stable brightness

- Maintain performance over time

Buyers should focus on usable lumens, not marketing figures.

Waterproofing & Materials Used

For IP-rated LED strips, price differences grow even larger.

Higher-cost waterproof LED strips use:

- UV-resistant silicone or PU

- Stable sealing structures

- Aging and water immersion testing

Lower-cost alternatives often suffer from:

- Yellowing

- Cracking

- Water ingress at cut points

Outdoor and humid applications expose these differences quickly.

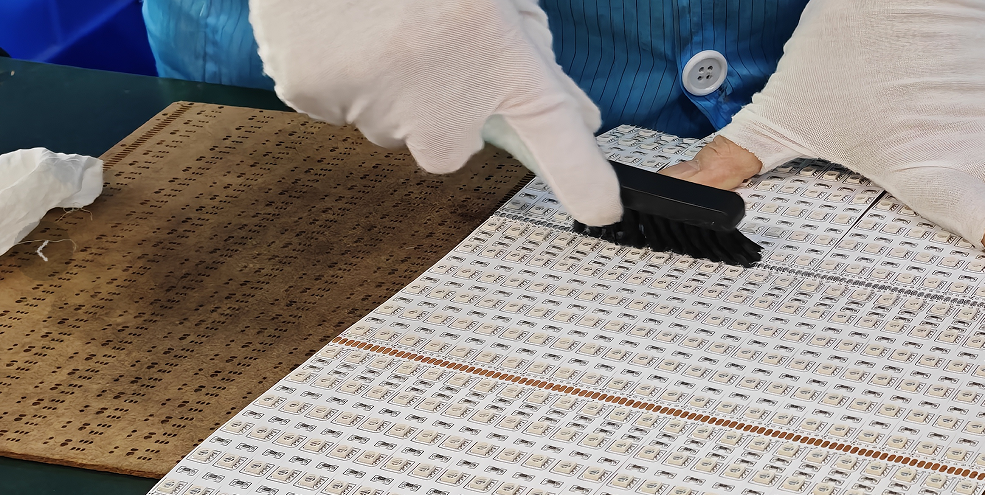

Manufacturing Process & Quality Control

Not all factories follow the same production standards.

Professional manufacturers invest in:

- Incoming material inspection

- In-process quality control

- Aging and burn-in tests

- Final inspection before shipment

These processes:

- Reduce failure rate

- Increase consistency

- Add labor and time cost

Low-price suppliers may skip or minimize these steps.

🏭 Quality control doesn’t appear on the datasheet — but it affects everything.

Certifications & Compliance Costs

For international markets, compliance is mandatory.

Certification-related costs include:

- Product testing

- Documentation

- Ongoing compliance maintenance

- Factory audits (for some markets)

Low-price LED strips may:

- Lack valid certificates

- Use expired or unrelated reports

- Shift compliance risk to the buyer

For Europe and North America, this risk can be far more expensive than the product itself.

Customization, Engineering & Support

OEM & ODM services add value — and cost.

Higher-priced suppliers often provide:

- Engineering consultation

- Custom PCB and circuit design

- Sample development

- Technical documentation

Cheaper quotes usually mean:

- No customization support

- Limited technical communication

- Standard products only

For professional projects, this difference matters.

After-Sales Risk & Long-Term Cost

The lowest price often hides the highest risk.

Hidden costs of cheap LED strips:

- Replacement labor

- Project delays

- Client complaints

- Reputation damage

Value-focused LED strips offer:

- Stable performance

- Lower maintenance

- Predictable lifespan

💡 Total cost of ownership matters more than unit price.

Why Two Similar LED Strips Can Have Very Different Prices

On the surface:

- Same voltage

- Same LED count

- Same wattage

In reality:

- Different LED grades

- Different PCB quality

- Different testing standards

- Different failure risks

Price reflects what you don’t immediately see.

How Buyers Should Evaluate LED Strip Pricing

Instead of asking “Why is this more expensive?”, buyers should ask:

- How stable is the LED source?

- How is color consistency controlled?

- What QC steps are in place?

- What support is available after delivery?

A transparent supplier should be able to explain their pricing clearly.

Conclusion

LED strip prices vary because quality, reliability, compliance, and support vary.

A low price may reduce upfront cost, but often increases long-term risk.

For professional applications, the smartest buyers focus on:

- Performance stability

- Consistency

- Compliance

- Long-term value

In LED strip lighting, you don’t just buy a product — you buy reliability.

Other articles:

How to light your kitchen-kitchen design lighting guide

From flat to fabulous: transform walls with LED lighting

This shelf lighting is magic: transform your space with LED strip lights

As a bespoke lighting solution provider, Yiholight specializes in high-quality LED strips, flex neon strip, LED downlight, LED track light. Our products are engineered for durability, brightness, and ease of installation—trusted by B2B customers across the globe.

Contact us today to explore the best LED lighting for your business!

© [Yiholight] and [www.yiholight.com]. Unauthorized use or duplication of this material is strictly prohibited without express written permission from the site’s author or owner. Excerpts and links may be used, provided full, clear credit is given to [Yiholight] and [www.yiholight.com], with appropriate, specific direction to the original content.