With the rapid growth of LED strip lighting in residential, commercial, and architectural projects, the market is now filled with thousands of options — often with huge price differences and very similar specifications on paper.

However, experienced buyers know that not all LED strips are created equal. A low-quality LED strip may look acceptable at first, but often leads to flickering, color inconsistency, premature failure, or costly maintenance problems later.

This article explains the 10 most important factors that determine LED strip quality, helping buyers, designers, and project managers make informed decisions and avoid common pitfalls.

Table of Contents

LED Chip Quality and Consistency

The LED chip is the core of any LED strip.

High-quality LED strips use:

- Stable, reputable LED chip suppliers

- Consistent binning for brightness and color

- Proven long-term reliability

- Low-quality LED chips often suffer from:

- Rapid lumen depreciation

- Color shift over time

- High failure rates

🔍 What buyers should check:

- LED brand or grade

- Luminous efficacy stability

- Color binning control (SDCM)

Color Consistency (CRI, SDCM & Binning Control)

Color quality is critical, especially for architectural, retail, and hospitality projects.

Key indicators of high-quality color:

- CRI ≥ 90 for professional applications

- Tight SDCM (≤3) for consistent appearance

- Controlled binning across production batches

Poor color control leads to visible differences between LED strips installed in the same space — a major issue in linear lighting designs.

💡 High-quality manufacturers manage color consistency at component and production levels, not just in final inspection.

PCB Design and Copper Thickness

The printed circuit board (PCB) is responsible for:

- Electrical stability

- Heat dissipation

- Mechanical strength

High-quality LED strip PCB features:

- Thick copper layers (2oz or more for high power)

- Uniform trace design

- High-quality flexible substrate

- Stable adhesion between layers

Thin or poorly designed PCBs increase resistance, heat buildup, and voltage drop.

Heat Dissipation Capability

Heat is the silent killer of LED strips. Even the best LED chips will degrade quickly if heat is not properly managed.

What affects heat dissipation:

- LED power density

- PCB material and thickness

- Installation method (aluminum profile vs direct mounting)

- High-quality LED strips are:

- Designed to work with aluminum profiles

- Tested under real operating temperatures

- Rated conservatively, not overdriven

🔥 Excessive heat causes lumen loss, color shift, and early failure.

Electrical Design & Circuit Stability

Electrical design plays a major role in long-term performance.

High-quality LED strips feature:

- Stable current distribution

- Proper resistor or constant-current design

- Optimized cutting length

- Reduced voltage drop over distance

Low-quality designs often prioritize cost, leading to:

- Uneven brightness

- Flickering

- Shortened lifespan

For long installations, professional manufacturers may use:

- 24V systems

- Constant-current designs

- Ultra-long-run circuits

Lumen Output & Efficiency (Real vs Claimed)

Many LED strips advertise impressive lumen numbers — but not all values are realistic.

High-quality LED strips provide:

- Honest lumen ratings

- Measured under standard test conditions

- Stable output over time

Low-quality products may:

- Inflate lumen values

- Ignore thermal degradation

- Drop brightness significantly after short use

📌 Buyers should focus on usable, sustained brightness — not marketing numbers.

Waterproofing & Environmental Protection

For outdoor or humid environments, protection level is critical.

Quality waterproof LED strips:

- Use stable silicone or PU materials

- Have properly sealed solder joints

- Are tested for aging and moisture resistance

Common IP options:

- IP20 – indoor dry areas

- IP65 – splash resistant

- IP67 / IP68 – outdoor or submerged use

Poor waterproofing often fails at:

- Cut points

- End caps

- Power connection areas

Adhesive Quality & Mechanical Reliability

While often overlooked, adhesive backing affects installation reliability.

High-quality LED strips use:

- Industrial-grade adhesive (e.g. 3M)

- Strong bonding to PCB

- Consistent adhesive application

Low-quality adhesive can:

- Fail under heat

- Peel over time

- Cause rework and installation complaints

Professional installations often combine adhesive with aluminum profiles and mounting clips.

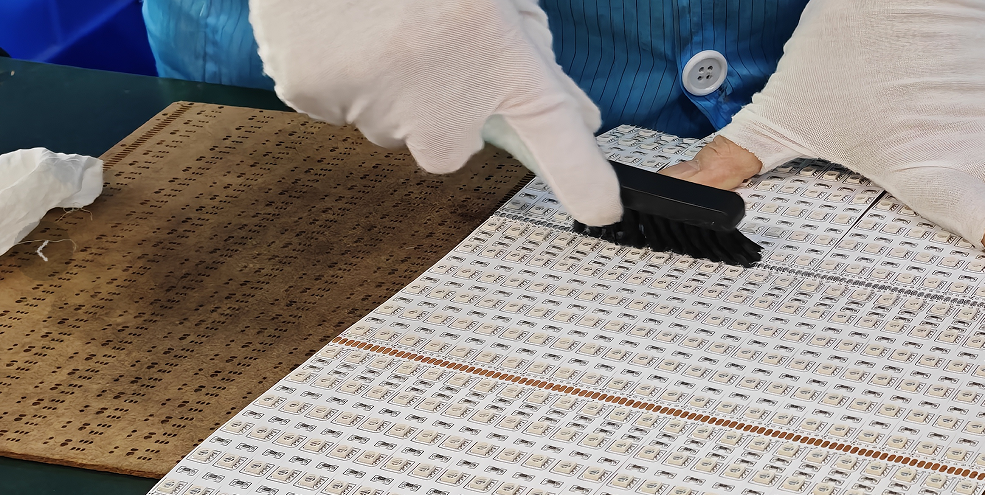

Manufacturing Process & Quality Control

A high-quality LED strip is not just about materials — it’s about process control.

Reliable manufacturers implement:

- Incoming material inspection

- In-process quality checks

- Aging and burn-in tests

- Final inspection before shipment

Without strict QC, even good components can result in inconsistent products.

🏭 Factory capability and quality systems matter as much as specifications.

Why Cheap LED Strips Often Cost More in the Long Run

Low-quality LED strips may save money upfront but often result in:

- Higher failure rates

- Inconsistent appearance

- Project delays

- Increased maintenance costs

- Damage to brand reputation

For commercial and architectural projects, stability and consistency always outweigh the lowest price.

How Buyers Can Identify a High-Quality LED Strip Supplier

Beyond the product itself, buyers should evaluate:

- Engineering support

- Customization capability (OEM & ODM)

- Communication efficiency

- Long-term cooperation mindset

- Proven export experience

A reliable supplier acts as a technical partner, not just a product vendor.

Conclusion

A high-quality LED strip is the result of careful design, controlled materials, strict manufacturing processes, and professional testing.

By understanding these 9 critical factors, buyers can confidently select LED strip products that deliver stable performance, consistent appearance, and long service life — especially in demanding professional applications.

Other articles:

How to light your kitchen-kitchen design lighting guide

From flat to fabulous: transform walls with LED lighting

This shelf lighting is magic: transform your space with LED strip lights

As a bespoke lighting solution provider, Yiholight specializes in high-quality LED strips, flex neon strip, LED downlight, LED track light. Our products are engineered for durability, brightness, and ease of installation—trusted by B2B customers across the globe.

Contact us today to explore the best LED lighting for your business!

© [Yiholight] and [www.yiholight.com]. Unauthorized use or duplication of this material is strictly prohibited without express written permission from the site’s author or owner. Excerpts and links may be used, provided full, clear credit is given to [Yiholight] and [www.yiholight.com], with appropriate, specific direction to the original content.