LED strip lighting is reliable, flexible, and long-lasting — but like any lighting product, problems can occur if the wrong product is selected, installed incorrectly, or paired with unsuitable components. Many LED strip issues seen in real projects are not product defects, but design, installation, or power-matching problems.

This article explains the most common LED strip lighting problems, their root causes, and practical solutions, helping designers, installers, and buyers avoid costly mistakes and ensure stable, long-term performance.

Table of Contents

LED Strip Not Turning On

Possible Causes

- No power supply or incorrect wiring

- Wrong input voltage

- Polarity reversed (for DC systems)

- Faulty connector or solder joint

How to Solve It

- Confirm the power supply is connected and switched on

- Verify that the power supply voltage matches the LED strip (12V, 24V, etc.)

- Check + / – polarity carefully

- Test with a multimeter or short test section

- Inspect connectors for loose contact

💡 Tip: Always test LED strips before final installation.

LED Strip Is Dim or Unevenly Bright

Possible Causes

- Voltage drop over long runs

- Insufficient power supply capacity

- Thin wiring causing resistance loss

- Low LED density strip used incorrectly

How to Solve It

- Use 24V LED strips instead of 12V for long runs

- Power from both ends or use parallel wiring

- Choose a power supply with at least 20–30% power margin

- Use thicker gauge wires

- Consider constant-current or ultra-long-run LED strips

LED Strip Flickering

Possible Causes

- Poor-quality or incompatible power supply

- PWM dimmer incompatibility

- Loose wiring or connectors

- Overloaded power supply

How to Solve It

- Use high-quality, flicker-free LED drivers

- Ensure dimmers are compatible with the LED strip type

- Tighten all connections

- Reduce load or upgrade power supply

💡 Tip: Flicker is often a power issue, not an LED strip issue.

LED Strip Overheating

Possible Causes

- No heat dissipation

- High-power strip installed directly on wood or plastic

- Poor ventilation

- Overdriving LEDs

How to Solve It

- Always install LED strips in aluminum profiles

- Avoid enclosing strips without airflow

- Use proper power ratings

- Reduce brightness if necessary

🔥 Why this matters: Overheating dramatically shortens LED lifespan and causes color shift.

Color Inconsistency Between LED Strips

Possible Causes

- Different LED bins or production batches

- Mixed suppliers or models

- Poor phosphor consistency

- Incorrect controller settings

How to Solve It

- Use LED strips from the same manufacturer and batch

- Specify tight color binning

- Use high-CRI, consistent-quality LEDs

- Calibrate RGB or tunable white systems properly

💡 Professional projects should always avoid mixing strip models.

LED Strip Fails Prematurely

Possible Causes

- Poor heat management

- Low-quality LEDs or PCB

- Excessive moisture exposure

- Overvoltage or unstable power

How to Solve It

- Choose LED strips with high-quality PCB and components

- Use certified power supplies

- Match IP rating to environment

- Follow manufacturer installation guidelines

Cutting or Reconnecting LED Strip Causes Failure

Possible Causes

- Cutting at incorrect points

- Damaging copper pads

- Poor soldering technique

- Incorrect connector type

How to Solve It

- Only cut at marked cutting points

- Use sharp tools

- Clean and tin pads before soldering

- Use reliable connectors designed for the strip width

✂️ Reminder: Not all LED strips are designed for free cutting.

LED Strip Not Dimming Properly

Possible Causes

- Incompatible dimmer

- Wrong control method (PWM vs CV)

- Driver minimum load issue

How to Solve It

- Match dimmer type to LED strip and driver

- Use recommended controllers

- Test dimming range before final installation

LED Strip Used Outdoors but Fails

Possible Causes

- Incorrect IP rating

- Poor sealing at cut points

- UV degradation

- Water ingress over time

How to Solve It

- Use IP67 or IP68 LED strips

- Properly seal cut ends

- Choose UV-resistant silicone or PU materials

- Install outdoor-rated power supplies

LED Strip Appears “Dotty” Instead of Smooth

Possible Causes

- Low LED density

- Insufficient diffuser distance

- Clear or thin diffuser cover

How to Solve It

- Use high-density or COB LED strips

- Increase distance between strip and diffuser

- Choose opal or frosted diffusers

💡 COB LED strips are ideal for dot-free lighting.

Adhesive Backing Fails

Possible Causes

- Dusty or oily surface

- High temperature

- Low-quality adhesive tape

How to Solve It

- Clean surface thoroughly

- Use aluminum profiles with clips

- Upgrade to stronger adhesive (e.g., 3M VHB)

- Avoid relying on adhesive alone in long-term installations

EMI or Signal Interference (Digital LED Strips)

Possible Causes

- Long data cables

- Poor grounding

- Electrical noise from power lines

How to Solve It

- Shorten data cable length

- Use signal amplifiers

- Proper grounding

- Use shielded cables where required

How to Prevent LED Strip Problems Before They Happen

Most LED strip issues can be avoided with proper planning.

Best Practices

- Choose the correct LED strip for the application

- Match voltage, power, and control systems

- Allow heat dissipation

- Use certified components

- Test the system before final installation

Why Professional LED Strip Selection Matters

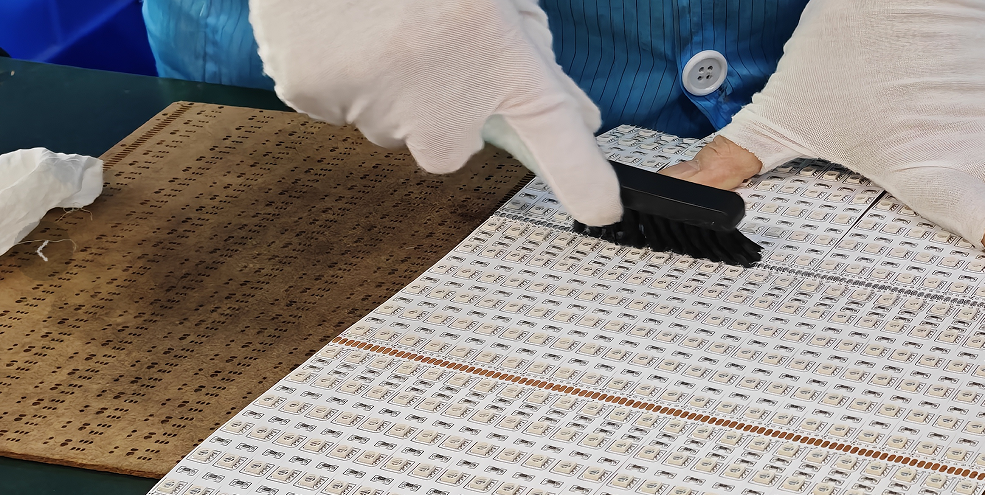

High-quality LED strip suppliers focus on:

- Stable LED sourcing

- Tight color binning

- Proper PCB design

- Strict quality control

- Clear technical guidance

These factors significantly reduce failure rates and long-term maintenance costs.

Conclusion

LED strip lighting problems are rarely mysterious. Most issues stem from incorrect selection, poor installation, or mismatched components. By understanding common problems and applying the right solutions, LED strip lighting can deliver years of stable, beautiful performance.

Whether for residential, commercial, or architectural projects, knowledge is the best tool for avoiding costly mistakes.

Other articles:

How to light your kitchen-kitchen design lighting guide

From flat to fabulous: transform walls with LED lighting

This shelf lighting is magic: transform your space with LED strip lights

As a bespoke lighting solution provider, Yiholight specializes in high-quality LED strips, flex neon strip, LED downlight, LED track light. Our products are engineered for durability, brightness, and ease of installation—trusted by B2B customers across the globe.

Contact us today to explore the best LED lighting for your business!

© [Yiholight] and [www.yiholight.com]. Unauthorized use or duplication of this material is strictly prohibited without express written permission from the site’s author or owner. Excerpts and links may be used, provided full, clear credit is given to [Yiholight] and [www.yiholight.com], with appropriate, specific direction to the original content.